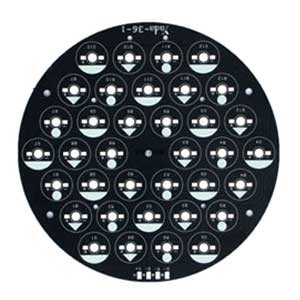

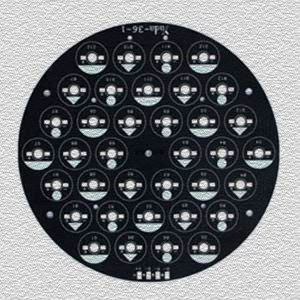

Product Detail:

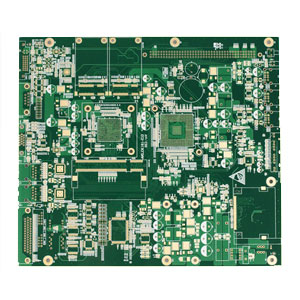

How are aluminum PCB board manufactured?

Aluminum PCB boards, also called metal-based PCBs, are composed of metal-based laminates covered by a copper foil circuit layer. They are made of alloy plates that are a combination of aluminum, magnesium and silumin (Al-Mg-Si). Aluminum PCBs deliver excellent electrical insulation, good thermal potential and high machining performance, and they differ from other PCBs in several important ways.

1. Base layer

This layer is composed of an aluminum alloy substrate. The use of aluminum makes this type of PCB an excellent choice for through-hole technology, which will be discussed later.

2. Heat insulation

This layer is an extremely important part of the PCB. It contains a ceramic polymer that has excellent viscoelastic properties, excellent heat resistance, and protects the PCB from mechanical and thermal stress.

3. Circuit layer

The circuit layer contains the aforementioned copper foil. Generally, PCB manufacturers use 1 to 10 ounces of copper foil.

4. Dielectric layer

When current flows through the circuit, the insulating dielectric layer absorbs heat. This is transferred to the aluminum layer, where the heat is dispersed.

Achieving the highest possible light output will result in increased heat. PCBs with improved thermal resistance can extend the life of the finished product. Qualified manufacturers will provide you with excellent protection, heat dissipation and component reliability. At MCL, we adhere to the extremely high standards required for your project.

Hecheng Electronic Technology Group Limited

Hecheng Electronic Technology Group Limited