What is SMT PCB assembly?

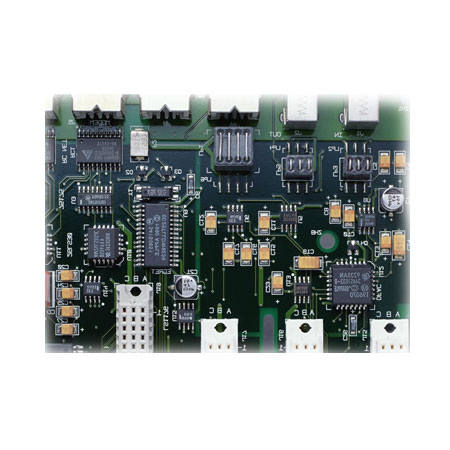

When it comes to the manufacture of electronic components, especially printed circuit boards, you may have heard of SMT or surface mount technology PCB assembly. But what does SMT PCB assembly mean? SMT PCB assembly is a method in which the electrical components are mounted directly onto the surface of a printed circuit board.

PCBEarth offers SMT PCB assembly at an affordable price. For any potential failures in SMT PCB assembly, we will provide solutions. PCBEarth ensures that you cooperate with qualified and reliable partners.

Advantages of SMT PCB Assembly?

There are several benefits associated with the surface mount technology PCB assembly:

1. SMT PCB assembly is expected to reduce material handling costs, lower circuit board costs, and unique manufacturing processes.2. The one of the most important benefits, especially in the design phase, not only reduces weight, but also reduces noise.

3. SMT components are excellent in space management. SMT components occupy the smallest space on the printed circuit board. SMT allows easy creation of small PCB designs because it can place components closer together on the PCB.

4. Unlike other forms of technology, the SMT process can be quickly put into production. In addition, the PCB structure manufactured under the SMT process is compact and the circuit speed is higher.

5. In through-hole assembly, lead wires pass through the holes to connect components. Because SMT PCB assembly components are soldered right onto the PCB, the overall makeup is far less complex.

6. SMT PCB assembly is very reliant on machines, and not so much on us humans. SMT PCB assembly is a process that's less prone to error because it's almost entirely automated.

Why choose our SMT PCB assembly service?

Our SMT PCB assembly services include the design of printed circuit boards and prototyping, Design for Manufacturability, low-volume, and high-volume to low-mix production. Our testing and inspection services feature state-of-the-art equipment coupled with some of the latest practices when it comes to testing your boards in addition to our automated machines.

PCBEarth understands that quality is paramount. Our clients look to us to provide highly-customized units that meet the highest standards for quality and reliability.PCBEarth performs all SMT PCB assembly services in SHENZHEN, China. Featuring over 20,000 square feet of production space, our facility is designed to ensure a high degree of quality control on any job. Our ISO 9001-registered quality management system is based on industry-recognized best practices and employs a series of scalable, monitored processes to encourage accountability and transparency in everything we do.

Difference Between SMT and SMD PCB assembly?

1. There are huge differences between surface mount technology. The first distinguishing factor is that one is the process-surface mount technology, and the other is the device-surface mount equipment.

2. SMT is intangible to the end consumer, and most people who don't know PCB may not know it. But SMD is more physical and tangible. These are the day to day electronic products from laptops, washing machines, and military-grade electronics.3.The surface mount technology and surface mount devices are technically different. Surface mount devices can be soldered manually by hand, but the situation is different when surface mount technology is involved.

What's the process for SMT PCB Aassembly?

As mentioned earlier, surface mount technology, or SMT for short, is a method for mounting electronic components on the surface of a printed circuit board, rather than inserting parts or components into holes like traditional printed circuit board assembly.

Surface mount technology is unique for many reasons. Nonetheless, the idea behind this technology is to reduce the cost of manufacturing printed circuit boards and more efficiently use the written circuit board space. With the introduction of SMT, it is now possible to build highly complex circuits into smaller components with excellent repeatability on a highly automated basis.The SMT PCB assembly process includes six basic steps that require the use of the latest technology:

1. Solder paste printing

2.Pick and place

3. Reflow soldering

4. Inspection and quality control developed by

5. Through-hole component insertion

6. Final inspection and functional test.

For a decade and counting, PCBEarth have been an industry provider for the provision of printed circuit board assembly services - supplying both flexible and rigid products to customers across the industrial, automotive, telecommunications, medical, aerospace, and other markets.

PCBEarth also performs the comprehensive testing and inspection services necessary to make sure that your products are functional and reliable. It starts with visual inspection under 100% magnification but can include automated optical inspection, in-circuit testing and functional testing.

If you have any questions or enquires, feel free to contact sales@PCBEarth.com , we will reply to you ASAP.

Hecheng Electronic Technology Group Limited

Hecheng Electronic Technology Group Limited