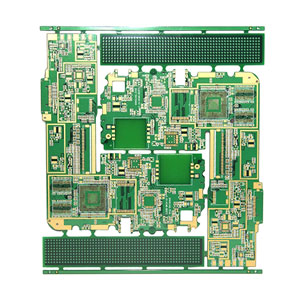

Product Detail:

If you are looking for an aluminum PCB manufacturer, Hecheng Fast Electronic Technology has extensive experience in manufacturing high thermal conductivity aluminum PCB, we provide first-class services and a wide range of high-tech options.

MCPCB, metal core PCB, thermal PCB-whichever name you prefer, they are all boards that use base metal materials as the heat sink part of the circuit board. These types of metal bases are usually made of aluminum (the most common) but can also be produced from copper.

Performance of aluminum PCB

1. Heat dissipation

Common PCB substrates such as FR4 and CEM3 are poor thermal conductors. If the heat of the electronic equipment cannot be dissipated in time, it will lead to high temperature failure of the electronic components. The aluminum substrate can solve this heat dissipation problem.

2. Thermal expansion

The aluminum substrate PCB can effectively solve the heat dissipation problem, thereby alleviating the thermal expansion and contraction of components on the printed circuit board of different materials, and improving the durability and reliability of the whole machine and electronic equipment. Especially the aluminum substrate can solve the problem of thermal expansion and contraction of SMT (surface mount technology).

3. Dimensional stability

The aluminum substrate printed circuit board has significantly higher stability than the insulating material of the printed circuit board. When heated from 30°C to 140-150°C, the dimensional change of the aluminum substrate is only 2.5-3.0%.

4. Other performance

The aluminum substrate printed circuit board has a shielding effect and can replace the brittle ceramic substrate. Aluminum substrate also helps to improve heat resistance and physical properties, reducing production costs and labor.

Hecheng Electronic Technology Group Limited

Hecheng Electronic Technology Group Limited