What is volume PCB assembly?

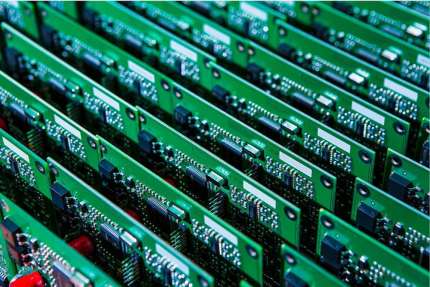

Volume PCB assembly includes low volume, medium volume and high volume, which refers to the standard precision printed circuit board assembly (PCBA) to advanced technology products, and the volume size ranges from 100 to 10,000.

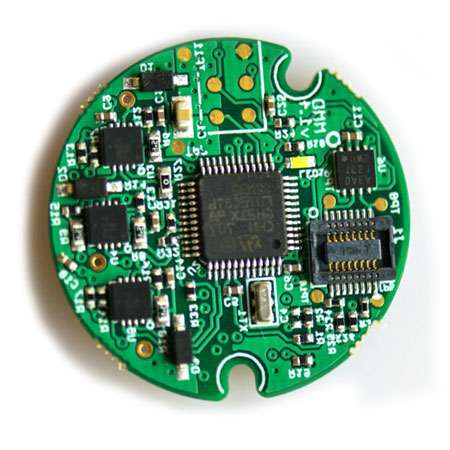

Hecheng Fast Electronic Technology is a low volume, medium volume and high volume manufacturer you can trust. We specialize in professional custom PCB prototype assembly jobs as well as full-scale, low- to mid-volume PCB production runs. We help and support customers to assemble their mid-volume and prototype PCB orders. With many years of rich experience in the field of printed circuit board assembly, we have gained expertise in fulfilling assembly orders from simple to highly complex, easy and fast turnaround time. Our competent engineering and manufacturing team helps many customers solve their PCB assembly problems.In the prototype / small quantity stages of a product, PCB assemblies are usually in an on-going development process that requires the ability to flexibly respond to revisions while still meeting strict performance and production scheduling requirements. Through the utilization of our versatile electronic contract manufacturing services and PCB assembly capabilities, Hecheng Fast Electronic Technology has developed cost-effective processes to meet the precision demands of advanced electronic prototype and small quantity runs.

Advantages of low volume PCB assembly services

1. Design changes-small PCB runs are ideal for prototyping. By letting customers know what their PCB looks like in the final stage, they can better decide whether to continue mass production or make adjustments to the design.

2. Testing and troubleshooting-Regardless of the scale of the operation, we will rigorously test all PCBs before shipping them to customers. This test can help reveal design flaws that prevent the PCB from functioning properly, or suggest changes to improve the PCB.3. Customized to meet your needs- High-mix low volume PCB assembly is perfect for products that vary in lot size, application and production processes. At Hecheng Fast Electronic Technology, our assembly line can effortlessly change product requirements, thereby maintaining production time.

Hecheng Fast Electronic Technology specializes in low-volume PCB assembly services with customized functions. We are equipped with advanced manufacturing facilities that can handle the most arduous tasks and achieve the expected quality. At Hecheng Fast Electronic Technology, we also provide turnkey PCB assembly services for low volume. We are responsible for the entire PCB assembly from parts procurement, PCB manufacturing, final assembly, testing and delivery. As a leading manufacturer of PCB assembly services for low volume, we ensure that your assembly work is completely risk-free and completed within a fast turnaround time.

What services can we provide?

1. Manufacturing Service Design (DFM): Through this service, we ensure that the production process runs smoothly and quickly without any errors. In order to achieve this goal, experts from Hecheng Fast Electronic Technology carefully analyzed and verified customer documents such as bill of materials (BOM), circuit diagrams, Gerber files, and assembly drawings. We also work closely with customers to understand their requirements before ordering production parts and starting the manufacturing process. Therefore, our Design for Manufacturing Service (DFM) helps reduce errors and speed up the assembly process, while enabling us to deliver products at low prices without delay.

2. Test Design Service (DFT): Through this service, we allow customers to determine the types of fixtures and probes, while letting them understand the limitations of the test program. By combining expertise with professional support processes, we ensure that PCB design/assembly is done the way you want.Most companies do not give due attention to PCB manufacturing in low volume. So, this is not good for small PCB enthusiasts and small companies. Hecheng Fast Electronic Technology always attaches importance to enthusiasts from large-volume printed circuit boards to low volume printed circuit boards. In addition, many companies do not give any concessions to low volume PCB assembly. However, we still provide our customers with the best offer.

Why choose our volume PCB assembly?

Hecheng Fast Electronic Technology provide various assembly solutions, including low volume, medium volume, high volume, commission, turnkey and SMT & THT PCB assembly.

1. Get customized PCB assembly that fully meets your business needs within 24 hours as soon as possible.2. We implement ISO9001:2015 international standard quality management system to provide the best assembly quality.

3.Adopt advanced machines and technologies, such as 30 Panasonic and Yamaha SMT production lines, German ESA selective wave soldering, solder paste inspection 3DSPI, AOI, X-ray, etc.

4. All our operation engineers have more than 10 years of PCB assembly experience.

5. One of our three major PCB factories, specializing in advanced PCB assembly.

6. We have multiple assembly lines to meet the most demanding requirements of customers.

7. Once the design is complete, we even provide prototypes for high-density printed circuit board assemblies. This helps customers understand the appearance of their PCB in the final stage.

8. All volume PCB assemblies undergo strict quality checks and inspections before they can be sent to the customers.

9. We can further customize our mid volume PCB assembly service according to the customer's production schedule and assembly requirements through separate transportation arrangements and personalized payment plans. In this way, the entire order volume can be distributed within a few months to meet customer needs.

Hecheng Fast Electronic Technology is firmly committed to providing high-quality volume PCB assembly services and PCB manufacturing to our customers. We have a variety of manufacturing, assembly and testing capabilities to help maintain quality consistency throughout the production process and save customers time and production costs.

Hecheng Electronic Technology Group Limited

Hecheng Electronic Technology Group Limited