What is prototype PCB assembly?

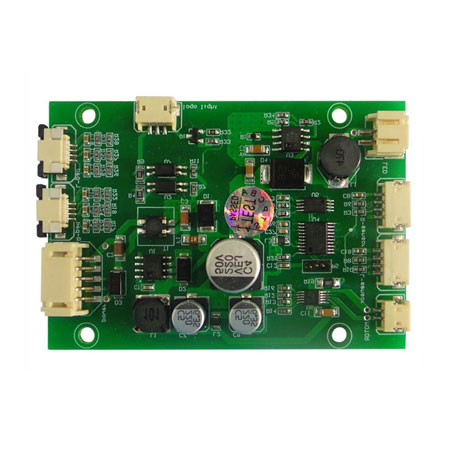

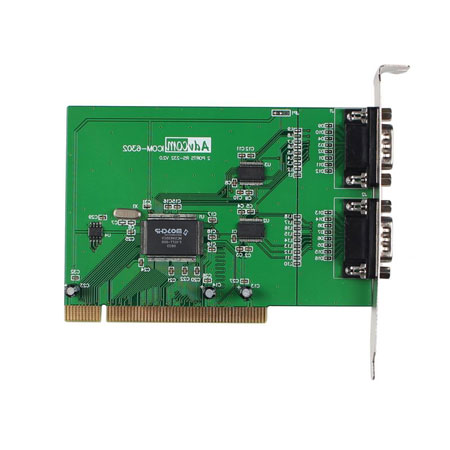

The term prototype PCB Assembly means a fast prototype PCBA used to test the function of new electronic designs. There are many names for prototype PCB assembly, common ones including surface-mount technology (SMT) PCB prototypes, PCBA prototype assembly, PCB sample assembly, etc.

PCB prototype is a crucial stage in product development. It enables the reduction of the risk of costly rework during mass production and helps to ensure the quality of the product, through verifying that there is no problem with the test product, finding bugs, and updating the design. Usually, before mass production, one electronic project will need 2-3 iterations of a prototype PCB assembly to make sure everything is in order.

What are the advantages of prototype PCB assembly?

Everyone in this business knows that the purpose of prototypes is to prove design concepts and eliminate errors—customers want to make sure that what they have created is going to work properly before committing to mass production. Thus, most companies prefer to get prototype PCB assembly services before getting their final design of circuit boards manufactured. The advantages of prototype PCB assembly are summarized as follows:

1. Reduced timeline and production costs.2. Eminently accurate, reliable prototype.

3. Manufacturing review and assistance.

4. Ability to test components individually.

5. Troubleshooting of the production process.

6. Production quantity estimate.

7. Visual model and scalability.

8. Complete projects efficiently.

What constitutes prototype PCB assembly cost?

At this point, we would like to briefly give an insight into what the prices for prototype PCB assembly generally consist of.

1.The components to be assembled;2.The number of individual circuit boards;

3.An SMD stencil for paste printing;

4.An additional effort for bonding heavier components to the underside;

5.The component shapes used and the manufacturability of the assembly;

6.The PCB technology deviates from the standard, e.g. Blind buried vias, micro vias, fine conductors;

7.Components that are difficult to obtain or discontinued are used;

8.One or both sides PCB--with the double-sided PCB assembly, almost all work steps occur twice;

Besides, the small size imposes higher requirements on manufacturing techniques and requires a high degree of precision in the PCB layout (template data, footprints, etc.). Of course, time factors also have an impact. If your project time is pressing, your order’s production schedule must be specially adjusted and quickly completed.

Why choose our prototype PCB assembly services?

We can help you manufacture prototypes of your printed circuit boards in the following specifications and capabilities:

Benefit optimization is an important cost consideration. We can reduce manufacturing costs and eliminate unforeseen costs. As an experienced PCB prototype manufacturer with turnkey service in PCB assembly, our large number of daily orders ensure we can greatly reduce the materials’ spending and labor cost, and we can provide cost-effective solutions for different demands and ensure the quality at the same time.

2. Varying quantities and quality control

We can provide you prototype printed circuit boards in various volume sizes and we handle complete PCB Assembly for prototype quantities from 1 to 25 boards. Thus, you can get the most intricate designs assembled for testing purposes. We put quality first at every stage of operation to organize incoming raw materials, process control, and perfect testing to provide you with the best PCB assembly.

3. Unique and flexible layout design

One of the excellent things about our prototype assembly area is that they give prominence to a unique layout design. Thus we are entitled to mix manual and automated part loading stations flexibly. We help you in manufacturing printed circuit board prototypes varying from one layer to eight layers.

4. Innovative processes for best results

We continuously improve our equipment and develop technologies and management systems adapted to flexible settings that are suitable for manufacturing very small amounts of PCBs without compromising mating time, cost, and quality. To assemble or prototype PCBs perfectly, each board must meet the highest quality standards and each process step is closely monitored and documented.

5. Fast delivery times

We are known for its fast turnaround times for prototype printed circuit boards. This allows us to deliver you the boards with your required design in less time. If we have all the parts available with us, then we can finish the assembly in 12 hours to 48 hours. We know how important timely PCB delivery is to our customers so that you can roll out your products faster and more efficiently.

What makes our service different?

The prototypes we design and produce for printed circuit boards can be used for many purposes, especially in the following requirements:

·Quality and design testingWe carry out the same manufacturing expertise to our prototype builds as we do with our production assemblies. Your prototype will go through a rapid manufacturing process. What makes our prototype service different is how is it fast-tracked. From engineering and design input to the final deliverable, each prototype project will be assigned to a dedicated expert who will walk through the product at every step of the manufacturing process.

·Manufacturing new product

·Modeling purpose

·Complex components

Our engineers are always ready to provide real-time support for your other design work to help your prototype complete. Whatever your project needs, our entire prototyping team is ready to deliver the highest quality, fast conversion products. At our company, we make sure to deliver the best quality PCBs. So, if you require a prototype PCB assembly manufacturer, then don’t hesitate to contact our skilled staff.

Hecheng Electronic Technology Group Limited

Hecheng Electronic Technology Group Limited