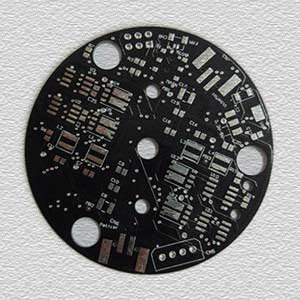

Product Detail:

Aluminum PCB are most used in LED and power conversion electronics. The strong light generated by the LED generates a lot of heat, and aluminum conducts this heat away from the component. Aluminum PCB can extend the life of the LED device and provide higher stability. You can find aluminum substrates in street lights, parking lights, and home lighting. They allow power converters to change current and regulate electronic equipment. Many creators in other industries also find uses for aluminum PCB, but they don't use them often.

Manufacturing Difficulties of Aluminum PCB

The manufacturing process of almost all aluminum PCBs is basically the same. Here, we will discuss the main manufacturing processes, difficulties and their solutions.

1. Copper Etching: the copper foil used in Aluminum PCBs is comparatively thicker. If the copper foil is over 3oz, and the etching requires width compensation. If it is not according to the demand of the design, the trace width will be out of tolerance after etching. Therefore, the trace width compensation should be designed accurately. The etching factor needs to be controlled during the manufacturing process.

2. Solder Mask Printing: due to the thick copper foil, the solder mask printing of aluminum PCB is difficult. This is because if the trace copper is too thick, the etched image will be very different between the trace surface and the substrate, and the solder mask printing will be difficult. Therefore, the use of secondary solder mask printing. The solder mask oil used should be of good quality. In some cases, the resin is filled first, and then the solder mask is filled.

3. Mechanical Manufacturing: the mechanical manufacturing process involves mechanical drilling, molding and v-scoring etc. which Is left on internal via. This tends to reduce electrical strength. Therefore, the electric milling and professional milling cutter should be utilized for low-volume manufacturing of products. The drilling parameters should be adjusted to prevent burr from generating. This will help your mechanical manufacturing.

Hecheng Electronic Technology Group Limited

Hecheng Electronic Technology Group Limited