What is PCB assembly?

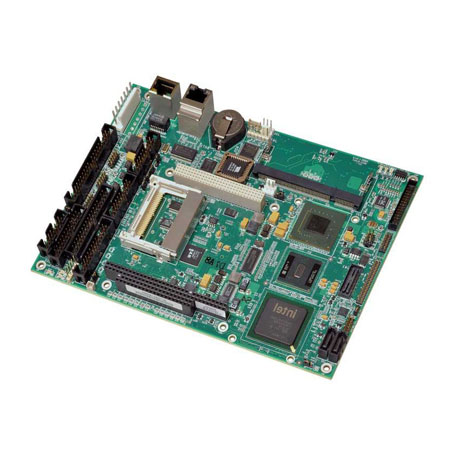

Printed Circuit Board Assembly (PCBA) is the finalized board that is obtained after all the components have been mounted on the printed circuit board (PCB). Printed circuit boards are the core of modern electronic equipment. Without them, many of the electronics we use would not be manufactured. PCBA is somewhat different from printed circuit board manufacturing which involves the manufacture of circuit boards. Assembly is to put assorted components on an empty board to develop a fully functional circuit board. Depending on the application of the electronic device, these components may include resistors, capacitors, integrated circuits (ICs), and others.

In addition, assemblers can complete the placement of components manually or mechanically. Mechanical assembly is the best choice for PCB assembly because of its high accuracy and precision.

How to assemble a Printed Circuit Board (PCB)?

Materials required for PCBA:

1. Printed Circuit Board (PCB).2. Electrical components such as resistors, capacitors, and others.

3. Soldering materials such as wire, preforms, bar, flux, and paste.

4. Soldering equipment such as wave soldering machine, surface mounter, SMT-Stencil, soldering fixture and testing tools, etc.

The following is the actual PCBA process:

Step1: DFM Check

The DFM check looks at all the design specifications of a PCB. Specifically, this check will find any issues that may severely affect the functionality of the final project.

Step2: Incoming Quality Control (IQC)

Before the start of SMT assembly, verify all incoming materials and handle quality issues. If they comply with our strict requirements, our IQC position will check related material issues.

Step 3: Solder Paste Stenciling

The solder paste is a thin and stainless-steel material. Before adding components to the board, solder paste needs to be added to those areas of the board where solder is required.

Step 4: Pick-and-Place

The pick and place machine places surface mount components on a prepared PCB. Mostly, this is a process achieved by the use of a unique robotic machine.

Step 5: Reflow Soldering

After that, the PCB board is transferred to the conveyor belt through the large reflow oven whose temperature is sufficient to melt the solder in the solder paste.

Step 6: Inspection and Quality Control

After completing reflow soldering, the board needs inspection for quality control. The quality of the board can be checked by several different inspection methods.

Step 7: Final Inspection & Functional Tests

After quality checks, final tests follow. These tests identify errors before a board can go into full manufacture. A final inspection will test the PCB for its functionality as it determines the success or failure of the process.

Step 8: Washing and Drying

Wash PCB in deionized water and use compressed air to dry, making the finished PCB available for packaging and transportation.

What are the factors affecting the cost of PCB assembly?

Factors affecting the price of PCB assembly are including:

·Size & thickness of the PCB

·Component type

·Number of parts, layers

·Soldering methods

·Inspection methods

·Impedance control

·Solder mask and silkscreen color, copper weight, etc.

The cost will vary relying on the component type and technology selected by the customers. Other factors that may make a difference in the cost are through-hole parts, surface-mount parts, fine pitch, leadless or BGA parts, etc.

What is the significance of PCB assembly services?

Due to the growth of electronic equipment manufacturing, the importance of efficient and precise PCB assembly services is increasing. Without a complete PCB assembly (an indispensable part of the mechanism), electronic devices such as computers, laptops, game consoles, calculators, consoles, and TVs cannot operate.

Firstly, it saves investment and labor costs: PCB assembly services provided by external companies can save the company a lot of investment and labor costs. Secondly, it helps to focus on core competitiveness: By outsourcing PCB assembly services from external service providers, the company can focus on its basic product development and core competitiveness.

Why partner with us for PCB assembly?

1. Affordable and competitive pricing

We are capable of cutting manufacturing costs and eliminate unforeseen expenses. This is because all checks we provided cut down on the number of scrapped boards. Nevertheless, we take into account all the elements and aim to offer competitive prices along with lead-free assembly. We try our utmost to save your money and time.

2. Reliable quality control

We put quality at the top of every stage of operation including PCB assembly and have the ability to organize incoming raw materials, process control, and perfect testing, to provide you with the best PCB assembly. One of the key reasons why we have become the preferred PCB manufacturer is that we adhere to the industry management system of strict quality standards applicable to our various fields.

3. The best services and capacities

We are the leading turn-key printed circuit board assembly solutions provider. From parts sourcing to PCB assembly, we can cover each one of your PCB requirements. We will help you in every step, and provide you with comprehensive professional knowledge and quality assurance. Also, we have big capabilities for SMT and SMD assembly, through-hole, and mixed technology PCB assemblies.

4. Real-time quotation

You can always get an instant quote for your custom PCB and PCB assembly inquiry, so you don’t have to wait a long time to know how much the order costs. In addition, to cope with the inconvenience caused by international time differences, we set up flexible working hours and work with customers to maximize timely response to customers.

5.On-time shipping

Through the years we are proud to have been keeping an on-time delivery that can only be achieved with the synergy of proper production management, well-trained professionals, and well-designed software. We understand how important it is to our customers that we deliver their PCBs on time, so you can launch your product faster and more efficiently.

Hecheng Electronic Technology Group Limited

Hecheng Electronic Technology Group Limited