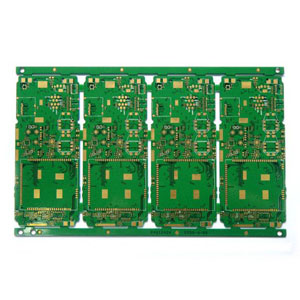

Product Detail:

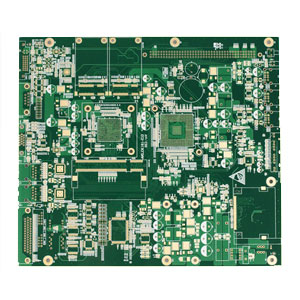

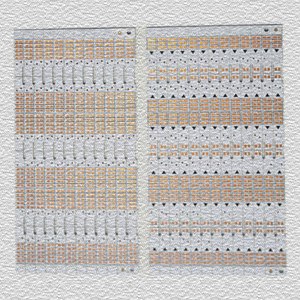

Why use aluminum for circuit boards?

Aluminum can actually transfer heat away from important components, thereby minimizing the harmful effects it may have on the circuit board. Higher durability: Aluminum provides products with strength and durability that ceramic or glass fiber substrates cannot provide.

Advantages and disadvantages of aluminum circuit board?

Aluminum circuit board is one of the most thermally conductive PCB options. They keep important components away from heat as much as possible to ensure that circuit damage is minimized. Due to their high heat resistance, they can handle higher density circuits and greater power levels. The base material made of aluminum alloy has a high level of physical durability, which reduces the risk of breakage. Compared with other metals, aluminum has a lower environmental impact in addition to its reasonable cost.

On the other hand, aluminum circuit board tend to have more niche uses than standard boards. Although their cost is lower than the cost of adding conductors to the copper board, their price is higher than a standard PCB without these components. If your application does not involve high temperatures, the investment in aluminum core may not pay off. If you plan to create a flexible circuit, the aluminum flexible PCB can only be bent to its initial position. It will bend to fit smaller electronic devices, but it won’t withstand the stress of vibration.

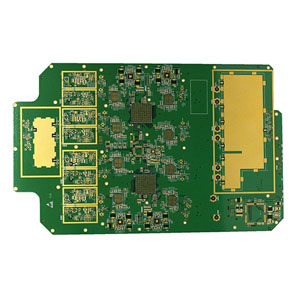

Hecheng Electronic Technology Group Limited

Hecheng Electronic Technology Group Limited