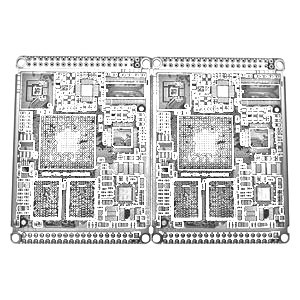

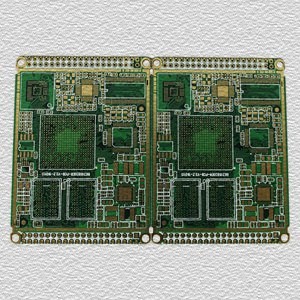

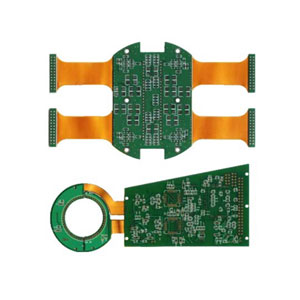

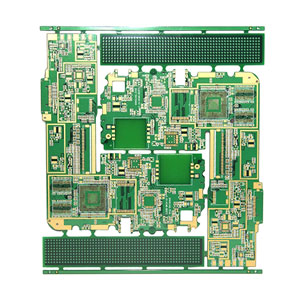

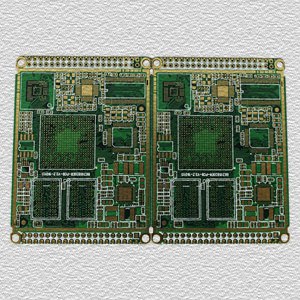

Product Detail:

10-layer PCBs are becoming more and more popular in the satellite, GPS, and memory module industries. Hecheng Fast Electronic Technology has provided services from prototype 10-layer PCB manufacturing to mass production for more than 9 years.

Hecheng Electronic Technology Group Limited

Hecheng Electronic Technology Group Limited