What are SMT Components?

SMT components are devices that use surface mount technology (SMT). SMT has almost total domination of the PCB creation process. Not only are they more efficient to produce, and smaller to transport, these little devices are also highly efficient. The various components used are designed specifically to be soldered directly to a board rather than wired between two points.SMT components are different from their leaded counterparts. they are not designed to be routed between two points, but are designed to be placed on the board and soldered to the board. Their leads do not go through holes in the board as might be expected for a traditional leaded component. With the level of adoption for surface mount technology, there is a huge variety of components available. The selection of components available in surface mount packages far exceeds the number available in traditional leaded forms.

What are the types of SMT components?

There are different styles of the package for different types of components. Broadly the package styles can be fitted into three categories: passive components, transistors and diodes, and integrated circuits, and these three categories of SMT components are viewed below.1) Passive SMDs: There is quite a variety of different packages used for passive SMDs. However, the majority of passive SMDs are either SMT resistors or SMT capacitors for which the package sizes are reasonably well standardized. Other components including coils, crystals, and others tend to have more individual requirements and hence their packages.

2) Integrated circuits

More information about general integrated circuits. Especially for SMDs, they can be very different depending on the required connectivity. There is a variety of packages that are used for integrated circuits. The package used depends upon the level of interconnectivity required. Because of the wide variation of requirements, there are several different packages available.

3) Transistors and diodes

SMT transistors and SMT diodes are often contained in a small plastic package. The connections are made via leads that emanate from the package and are bent so that they touch the board. Three leads are always used for these packages. In this way, it is easy to identify which way round the device must go.

What are the advantages of SMT components?

Today, the vast majority of electronic products are manufactured using surface mount technology (SMT). Compared with traditional routing circuits, equipment and products using SMT have many advantages. These devices are called SMT components or SMDs.The main advantage of SMT is that it will assists electronics manufacturers to produce highly complex products during shorter periods of their time, increasing the general production rates while reducing production costs.

·Low stray inductance and capacitance:

Given the small size of the components, the levels of spurious inductance and capacitance are much smaller - SMT resistors function in a way that is closer to the perfect resistor than that of a leaded resistor. Similarly, an SMT capacitor will exhibit much lower parasitic inductance. Therefore, faster speeds and higher frequencies are possible with standard SMT components than would be possible with leaded equivalents.

·Lower power level:

The power rating of surface mount components is of vital significance. The surface mount resistor is a particular example. A standard leaded resistor can dissipate at least 0.25 watts. For surface mount resistors, there is much less dissipation due to their much smaller size. Be aware of this and check the manufacturer’s data.

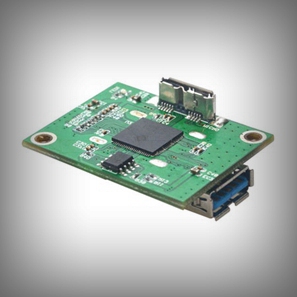

·Smaller and denser circuits:

The need to promote more functions in smaller and smaller volumes is a general trend in the entire electronics industry, so surface mount technology helps to achieve miniaturization to a large extent. These components can be made smaller, and compared to traditional leaded components, they can be more tightly mounted on the printed circuit board.

What are the factors that affect SMT components costs?

Currently, the price of SMT components costs varies from market to market, depending on:1. Unit price by process

2. According to the number of orders

3. The difficulty of pressing the board

4. Boot fee

5. Proofing fee

6. Steel net fee

Why Choose us for SMT components services?

1. Offers the lowest costs:We are continuously driven to become more efficient and reduce costs. We promise to offer customers the most economic components forever. We dedicate ourselves to providing the most sustainable solutions and offering excellent quality SMT components at the lowest possible price. That’s why we don’t have any hidden charges. Also, we offer the lowest costs in the industry for design and tooling, all while maintaining the highest grade quality systems and certifications.

2. Realize easier ordering:

Ordering components here is extremely easy. We make it easy for you to get a quote online instantly, and our self-service platform takes you a few minutes to upload files and order boards. We are fully transparent in our operations, you can know everything about your orders in real-time since every step can be tracked and informed on us.

3. Reliable and superior quality:

Ensuring quality and its consistent improvement are the two main guidelines of our company. We are continuously investing top-level base materials and advanced equipment for fully automated production lines, which enables us to offer our customers high throughput with consistently high quality.

4. Multiple testing before shipping:

First, we provide automatic optical checks, i.e. automatic visual inspection of components used for scanning boards, and scan the board in an extremely fine manner to check for any defects or faults. It is applied after Hot Air Solder Leveling. Then, flying probe testing uses electro-mechanically controlled probes to access parts on the board, similar to ICT. Last, apply final quality checks before shipping.

5. Shorten turnaround time:

Our smart platform automatically collects and analyzes the data collected by the sensors and monitoring devices on the equipment, and helps us take corrective actions to improve efficiency. Second, we use the available capacity of the factory network so that the system can match your order with one of the most suitable factories in the shortest turnaround time.

Hecheng Electronic Technology Group Limited

Hecheng Electronic Technology Group Limited