What is the PCB population?

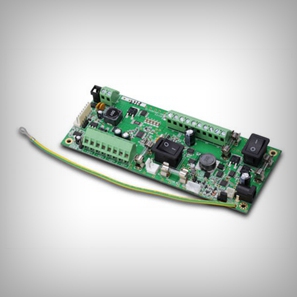

PCB population is the process of connecting the electronic components with the wirings of printed circuit boards. The traces or conductive pathways engraved in the laminated copper sheets of PCBs are used within a non-conductive substrate in order to form the assembly.Speaking of the PCB population, it is the heart of electronics. The boards are made by using metal parts. They are completely held together along with epoxy as well as insulated with the solder mask. Due to the solder mask, these boards feature a green color. These are the specialized features of these boards that will increase the importance of the PCB population.

How to populate a Printed Circuit Board (PCB)?

The PCB population process is simple and consists of several automated and manual steps. To help you better understand the process of the PCB population from start to finish, we explain each step in more detail below.Things required for the PCB population:

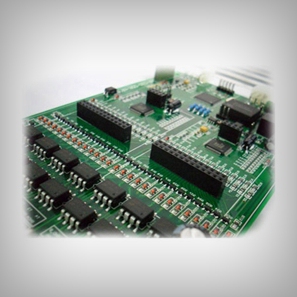

• Substrate: It is the base material for PCBs and gives PCBs their rigidity.• Copper: A thin layer of conductive copper foil is added to each functional side of the PCB, which is the layer of copper traces.

• Solder mask: It insulates copper traces from unintentionally contacting other conductive materials, which could result in a short. In other words, the solder keeps everything in its place.

• Silkscreen: A white silkscreen is a final layer that adds labels to the PCB in the form of characters and symbols. This helps indicate the functionality of each component on the board.

Except for substrates, these materials and components of all PCBs remain essentially the same. PCB substrates vary according to specific quality (e.g. cost and bendability), and each designer looks for them in their finished products.

The following is the actual PCB population process:

Step 1: Solder Paste StencilingThe first step of the PCB population is applying a solder paste to the board. This process is like screen-printing a shirt, except instead of a mask, a thin, stainless-steel stencil is placed over the PCB. This allows assemblers to apply solder paste only to certain parts of the would-be PCB. These parts are where components will sit in the finished PCB.

Step 2: Pick and Place

After applying the solder paste to the PCB board, the PCBA process moves on to the pick and place machine, a robotic device places surface mount components, or SMDs, on a prepared PCB. These SMDs are then soldered onto the surface of the board in the next step of the PCBA process.

Step 3: Reflow Soldering

Once the solder paste and surface mount components are all in place, they need to remain there. So after the pick and place process concludes, the PCB board is transferred to a conveyor belt. Once the solder melts, the PCB continues to move through the oven, which allows the melted solder to cool and solidify in a controlled manner. This creates a permanent solder joint to connect the SMDs to the PCB.

Step 4: Inspection and Quality Control

Checking for errors and dislocations can involve one of several different ways. The most common inspection methods include Manual Checks; Automatic Optical Inspection; X-ray Inspection. Generally, movement during the reflow process can result in poor connection quality or complete loss of connection.

What is the significance of PCB population services?

With the development of the electronic equipment manufacturing industry, the importance of efficient and precise PCB population services is increasing. Without a complete PCB population, electronic devices such as computers, laptops, game consoles, calculators, game consoles, and TVs will not operate.First of all, it can save investment and labor costs: PCB population services provided by external companies can save the company a lot of investment and labor costs. Second, it helps to focus on core competitiveness: By outsourcing PCB population services from external service providers, the company can focus on its basic product development and core competitiveness.

Why partner with us for the PCB population?

1. Certified quality standards:It is critical to the reliable and effective performance of your electronic components, not to mention the overall success of your manufacturing operations, just like your printed circuit boards, you cannot sacrifice anything in terms of quality. When you choose us as a circuit board supplier, you will get a company with a history of several years to provide high-quality PCB solutions to a global customer base. At each stage of operation, we put quality first.

2. Excellent customer service:

We want to offer the highest value PCB services and the greatest trading experience with smooth and efficient customer service. These are just some of the things our customers like about us: instant online quoting, ordering, and reordering features; quality guaranteed services; knowledgeable support team available via phone and email; free DFM check by professional engineers; no additional tooling charge for PCB reorders, etc.

3. Cost-saving doctrine:

We don’t have any minimum lot requirements, so you never have to buy more than what you need. We don’t charge tooling with our Standard Spec, and we also waive tooling again if you reorder your Standard Spec order as a Custom Spec order. Once we understand your specific needs, we will quickly work out a tailored integrated solution to meet your expenses and cost reduction targets.

4. Time-saving principle:

As a medium-sized company, we are able to respond fully to the needs of our customers and provide timely and personalized services that large companies cannot match. we will always keep in touch with you and keep you in the whole process from manufacturing to populating from the beginning to the end of the project. This can help you save money and pressure by reducing PCB costs, shortening waiting time, and providing higher quality products.

5. Quick quotation and delivery:

We have around-the-clock tech support available, and customers can receive instant quotes on orders and reorders. We are not a broker, which means that not only are we able to take care of the manufacturing at the facility, but it also means that we can ship out very quickly. In fact, it is sometimes possible to have orders shipped out on the same day that they are placed.

Hecheng Electronic Technology Group Limited

Hecheng Electronic Technology Group Limited