1. Solvent cleaner

Solvent cleaner can be divided into hydrocarbon solvents, halogenated solvents and fluorinated solvents. Solvent cleaning agent is a self-cleaning and low residue cleaning solvent. Its disadvantage is that it is easy to evaporate and volatilize, so it needs special attention in storage. Due to the requirements of environmental protection policies, halogenated solvents and fluorinated solvents are rarely used in recent years. When using hydrocarbon cleaning solvent, we should be paid attention to the fire prevention measures of machines and environment, and also should be considered the volatile organic compounds leak proof treatments. Only after these conditions are handled, hydrocarbon solvent cleaning solvent can be used in small batch PCB assembly proofing. Hydrocarbon cleaning solvent has a good effect on some rosin type and some cleaning free flux residues, oil stains and dirt.

Water-soluble cleaning solvent can be used in most scenarios. When selecting water-soluble cleaning solvent , the limitations of circuit board surface, metallization and compatibility should be considered. Including the compatibility of lead oxide reactants, white metal, yellow metal, ink marks and coating materials, and also the size, spacing and complexity of assemblies. The components of different types of flux residues are different, and the Water-soluble cleaning solvent cleaning the materials have different ability to remove welding residues.

When we know the composition of residues left on PCB assembly circuit board, we can choose whether to use solvent cleaner or Water-soluble cleaning solvent according to the actual needs. When the cleaning conditions are met, we also need to consider environmental protection.

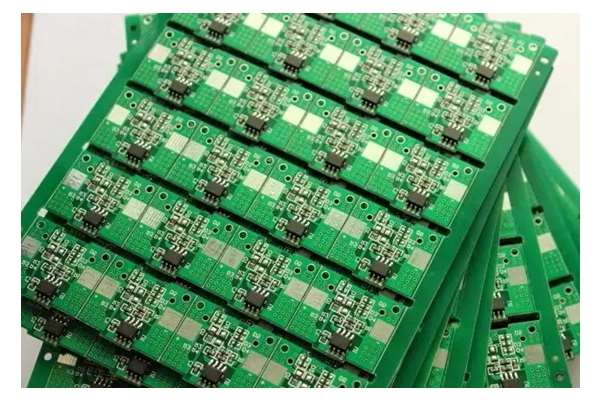

If you want to know more about PCB assembly, welcome to click: pcbearth.com. PCBearth have been providing PCB assembly more than 10 years to meeting the needs of our customers from different industries in terms of cost-effectiveness, quality , delivery and any other requests.

Hecheng Electronic Technology Group Limited

Hecheng Electronic Technology Group Limited